How to fit wrought iron stair spindles

How to fit wrought iron stair spindles

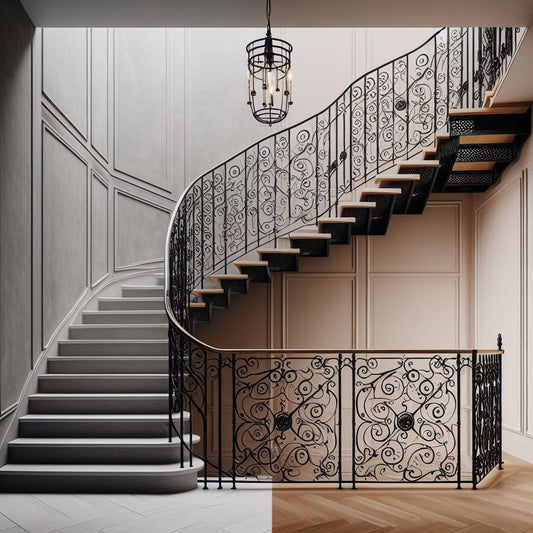

If you are looking for a way to update your staircase, you might want to consider installing wrought iron stair spindles. Wrought iron spindles can add a touch of elegance and style to your home, and they are not too difficult to install by yourself. Here are the steps you need to follow to fit wrought iron stair spindles:

1. Decide on your design. There are many types of wrought iron spindles to choose from, such as plain, twisted, knuckle, scroll, basket and more you can check out more types in are range . You can also mix and match different patterns to create a unique look. You can find some inspiration here online .or visit a local store that sells wrought iron spindles.

2. Remove existing spindles. If you have wooden spindles, you will need to remove them first. You can use a saw or a pry bar to cut or pry them out of the handrail and the base rail. Be careful not to damage the rails or the stairs. You might need to fill in any holes or gaps with wood filler and sand them smooth.

3. Measure and cut new spindles with Metal saw or angle grinder 0r have them custom made before you start you're project . Once you have your new wrought iron spindles, you will need to measure and cut them to fit your staircase. You can use a tape measure and a marker to mark where you want to cut the spindles. You can use a hacksaw or an angle grinder to cut the metal. Make sure you wear safety goggles and gloves when cutting metal.

4. Install and glue. To install the new spindles, you will need some wrought iron baluster shoes and some glue. The shoes are metal pieces that cover the ends of the spindles and attach them to the rails. You can slide the shoes onto the spindles before or after cutting them. To install the spindles, you will need to drill holes in the handrail and the base rail where you want to insert the spindles. You can use a drill bit that is slightly smaller than the diameter of the spindles. Then, you can apply some glue to the ends of the spindles and insert them into the holes. You can use a rubber mallet to tap them in place if needed. Finally, you can slide the shoes over the ends of the spindles and secure them with glue or screws.

For installing wrought iron stair spindles, you’ll need the following tools:

How to fit wrought iron stair spindles

-

Safety equipment:

Safety glasses: To protect your eyes while cutting and handling materials. - Work gloves: To safeguard your hands during installation.

-

Measuring Tools:

Tape measure: For accurate measurements of the railing height and spindle lengths. - Level: To ensure the spindles are straight and aligned.

-

Cutting Tools:

Metal saw or angle grinder: To cut the wrought iron spindles to the desired length. - Hacksaw: Useful for smaller cuts or if you don’t have an angle grinder.

-

Fastening Tools:

Drill: To create holes for the spindles in the handrail and base. - Drill bits: Sized appropriately for the spindles.

- Screwdriver : For securing the spindles in place.

-

Adhesive:

- Wood glue: To attach the spindles to the railing.

-

Optional Tools:

- Baluster shoes: If you want to cover the gap between the spindle and the floor.

- When installing wrought iron stair spindles, safety is paramount. Here are some precautions to keep in mind:

-

Eye Protection:

- Wear safety glasses to shield your eyes from metal shards or debris while cutting or handling materials.

-

Hand Protection:

- Work gloves are essential to protect your hands from sharp edges and potential injuries.

-

Stability and Balance:

Maintain a stable footing while working on the stairs or ladder. - Use a sturdy ladder if needed to reach higher areas.

-

Cutting Safety:

When using a metal saw or angle grinder, follow these guidelines: Secure the material: Clamp the wrought iron spindle securely before cutting. - Cut away from yourself: Position the tool so that sparks and debris move away from your body.

- Wear a dust mask: Protect your respiratory system from metal dust.

- Keep hands clear: Avoid placing your hands near the cutting area.

- If using a hacksaw, maintain a controlled motion to prevent slipping.

-

Drilling Precautions:

- When drilling holes for spindles:

- Mark the locations accurately before drilling.

- Use the correct drill bit size to match the spindles.

- Hold the drill firmly to prevent it from slipping.

-

Glue Application:

- When applying wood glue to attach the spindles:

- Follow manufacturer instructions for the specific glue you’re using.

- Wipe off excess glue to avoid visible residue.

-

Baluster Shoes (Optional):

- If using baluster shoes to cover gaps at the bottom of the spindles:

- Ensure they fit securely and are properly aligned.

Take Your Time:

Powder coating is an excellent option for finishing wrought iron spindles.

Here’s what you need to know:

How to fit wrought iron stair spindles

-

What Is Powder Coating?:

- Powder coating involves applying a dry, fine plastic powder to the metal surface.

- The powder becomes charged with static electricity and adheres to the metal.

- the powder coated parts are baked in an oven.

- Advantages of Powder Coating:

- Durability: Powder-coated finishes are resistant to chipping, scratching, and fading.

- Aesthetic Appeal: Achieve a smooth, even finish in various colours can be chosen from a Ral chart .

- Rust Protection: Powder coating helps prevent rust and corrosion.

-

Process for Powder Coating Wrought Iron Spindles:

Preparation: Clean the spindles thoroughly to remove dirt, rust, and old paint. - Application:Spray the dry powder evenly onto the spindles.

- The static charge ensures uniform coverage.

- Baking: Place the spindles in an oven where the powder melts and adheres to the metal.

-

Professional or DIY?:

Professional Service: Many companies specialize in powder coating wrought iron. They handle the entire process. - DIY Option: If you’re confident, you can explore DIY powder coating kits available in the market. Follow the instructions carefully.

-

Painting or finishing wrought iron spindles can enhance their appearance and protect them from rust. Here are some steps to achieve a beautiful finish :

Surface Preparation :

Clean the Spindles: Remove any dirt, dust, or existing paint from the spindles. Use a wire brush or sandpaper to create a smooth surface. - Wipe Down: After sanding, wipe down the spindles with a damp cloth to remove residue.

-

Choose Your Finish:

Painting: Primer: Apply an epoxy primer designed for metal surfaces. This helps the paint adhere better. - Paint Colour: Select a high-quality exterior-grade enamel paint. Consider using a “direct-to-metal” (DTM) paint with rust-inhibiting properties.

- Application: Use a brush for precise application or spray paint for faster coverage.

- Apply two light coats, allowing each coat to dry completely.

- Faux Wrought Iron Finish: Base Coat: Paint the spindles with a dark gray or black base coat.

- Wrought Iron Paint: Shake the wrought iron paint well to distribute iron filings. Apply it over the base coat.

- Aged Look (Optional): For an aged appearance, apply a rust solution with a disposable brush.

-

Allow Proper Drying Time:

- Follow the manufacturer’s instructions for drying times between coats.

-

Maintaining your wrought iron stair spindles is key to keeping them looking great and preserving their longevity. Here are some tips for proper care:

-

Regular Dusting:

- Use a lint-free microfiber cloth or a feather duster to remove dust. avoid using harsh chemical cleaners on wrought iron as could cause damage to spindles over time.

-

Deep Cleaning:

- For a more thorough clean, especially if the spindles have been neglected, use a solution of 2 parts water and 1 part white distilled vinegar. Use a lightly soaked towel and wipe clean.

- Rust Prevention:

-

Wipe-Downs:

- For quick maintenance, a simple wipe-down with a damp cloth can keep your spindles looking as good as new.

-

Avoid Moisture:

- Keep the spindles dry. Prolonged exposure to moisture can lead to rust, so it’s important to address any spills or dampness promptly.

-

By following these steps, you can ensure that your wrought iron stair spindles remain in excellent condition for years to come. Remember, consistency is key in maintenance to avoid the build up of dirt and potential rust.